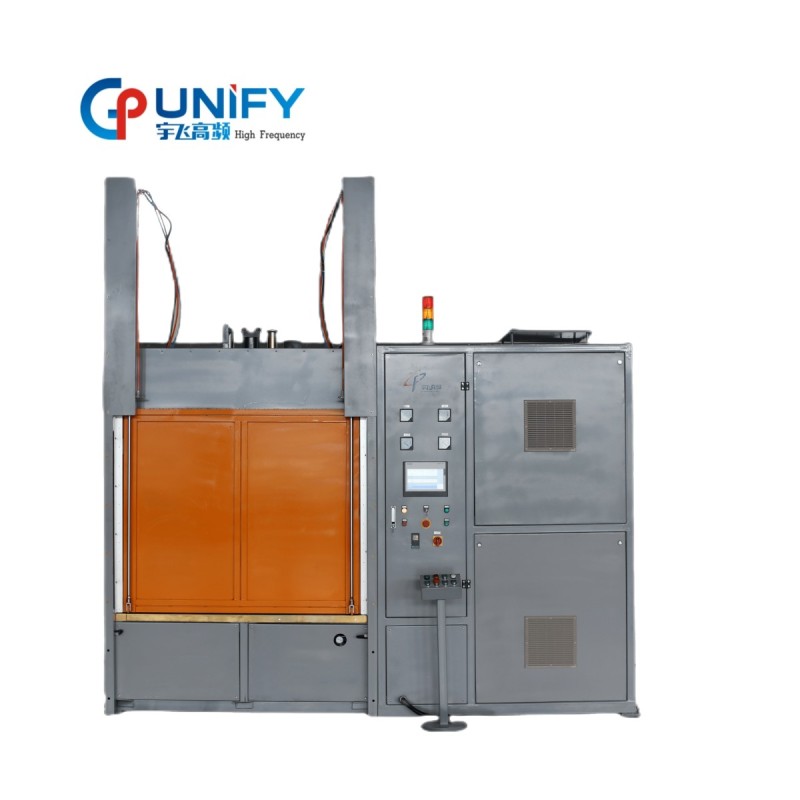

High Frequency Pvc Floor Carpet Welding Clasp Install Machine

- Information

- Product Description

- Video

- Download

High Frequency Pvc Floor Carpet Welding Machine

Machine Features:

PLC control, touch screen operation.

Prestore of a large amount of technical parameters.

Set technology parameters digitally in different times.

Fault self-diagnosis and screen displaying.

Add automatic installation of car carpet fixing buckle system, automatic loading and installation.

It can reliably identify different molds, automatically retrieve the set programming parameters, and put into production accurately and quickly

Specifications:

Type | Power KW | Frequency MHz | Tube model | Pressure T | Working electrode size | Remark |

YF-HFM8-B | 8 | 27.12 | 7T69R | 5T | Customized according to car carpet | pneumatic |

YF-HFM8-C | 7T69R | >5T | hydraulic touch screen display Automatic Power Tracking | |||

YF-HFM15-B | 15 | 8T85 | >10T | |||

YF-HFM15-C | 8T85 | >10T | ||||

YF-HFM25-B | 25 | 8T25R | >10T | |||

YF-HFM25-C | 8T25R | >10T | ||||

| YF-HFM35-B | 35 | 8T87R | >10T | |||

| YF-HFM35-C | 8T87R | >10T |

High Frequency Pvc Floor Carpet Welding Clasp Install Machine application range:

Suitable for automotive carpet welding work. It can weld a variety of material combinations, and can weld wire loop carpets, velvet blankets, and velvet blankets + velvet blankets and other forms.

About High Frequency Pvc Floor Carpet Welding Clasp Install Machine:

Power automatic tracking principle: According to the thickness, composition and conductive impurity content of the heat-sealing material, the meson impedance of the heat-sealing material can be fed back to the PLC and the control device, and the PLC and the control device can automatically adjust the high-frequency heat-sealing current and power, and automatically adjust the mold at different times The pressure ensures the effect and quality of heat sealing and welding, and effectively reduces the scrap rate.

Advantages: Due to the different suppliers of carpet raw materials, there are differences in each batch of carpet raw materials, and each piece also has the individuality of uneven material thickness, uneven material composition, and conductive impurity content at the heat-sealing position. The power automatic tracking function can better solve the phenomenon of defective products and waste products caused by excessive heat-sealing welding or heat-sealing welding. Tracking can effectively avoid the breakdown caused by material differentiation and cause waste.

In addition, due to the thicker carpet material in the passenger compartment, the current changes slowly in the natural state. The automatic power tracking will match the power to the best in the shortest time, and the production efficiency can be improved and the production cycle shortened through automatic current adjustment. Due to automatic control, the operation The operator does not have to monitor and adjust parameters such as equipment current at all times, saving labor.

The power automatic tracking function can not only accurately control the welding power, but also is indispensable for materials that are not easy to melt, such as PE and other environmentally friendly materials that do not contain PVC.

Details:This carpet welding machine is equipped with a mold changing trolley, which is easy to replace the mold and clamps the mold pneumatically.

Welding renderings

Equipped with a mold changing trolley, the trolley is at the same height as the lower plate, and the mold can be removed or installed with the trolley, which is convenient and labor-saving.