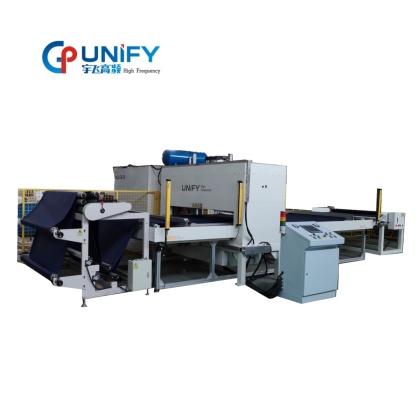

High Frequency Pvc Water Bed Welding Machine

- Information

- Product Description

- Video

- Download

High Frequency Pvc Water Bed Welding Machine

Machine Features:

Model | YF- HFM8-A HFM8-B HFM8-C | YF- HFM15-A HFM15-B HFM15-C | YF- HFM25-A HFM25-B HFM25-C | YF- HFM35-A HFM35-B HFM35-C | |

Power(Kw) | 8kw | 15kw | 25kw | 35kw | |

Power Supply | AC3 ∅380v 50/60Hz | ||||

Frequency | 27.12-13.56MHz | ||||

Tube | 7T69R(made in China) | 834(made in China) | 8T25R(imported Toshiba) | 8T87R(imported Toshiba) | |

Sparkproof Tube | 5557(USA) | ||||

Cooling Mode | Air-cooled | ||||

Pressurization | Hydraulic/Pneumatic | ||||

Upper Electrode Size | 450*850mm | 1000*1200mm 900*1000mm 900*1000mm | 1200*1500mm 1000*1300mm 1000*1300mm | 1280*2000mm 1280*2000mm 1200*1800mm | |

High Frequency Pvc Water Bed Welding Machine application range:

This high-frequency welding machine is suitable for the production of air mattresses, water beds, anti-decubitus mattresses and other products that require high-frequency welding.

About High Frequency Pvc Water Bed Welding Machine:

It is suitable for the processing of PVC products such as air mattresses, anti-decubitus mattresses, and water beds.

1. Automatic feeding, fast cutting, reducing the time during feeding and cutting.

2. The pulley is automatically welded in blocks without manual operation, which greatly avoids the waste caused by human factors.

3. The slideway of the equipment is widened by 2 meters, and the width of the roller is 2.2 meters. Suitable for double bed mattress welding, also suitable for single products.

4. Reduce the single welding area and strengthen the welding strength. improve product quality.

5. The whole line is shielded, and the radiation of low-power equipment is negligible.

6. There are very few manual operations, and the equipment only needs one person to operate. Labor costs are reduced.

Simple operation and high degree of automation.

Can be customized according to customer products.