Non-woven Cable water blocking tape Direct Heat welding machine

- Information

- Product Description

- Video

- Download

Non-woven Cable water blocking tape Direct Heat welding machine

Machine Features:

Seam width | 30 mm (10,15,25 mm optional) |

Welding length | 1000mm |

Welding cycle time | 3-10 seconds* |

Maximum temperature | 260°C |

Power supply | 3x400 V; 50 Hz |

Average power consumption | Power capacity15 kVA |

Compressed air | 6 bar |

Maximum storage parameter | 20 sets |

Dimension | L 2050 x W 950 x H 2120mm |

Weight | 1500kg |

Non-woven Direct Heat Welding Machine application range:

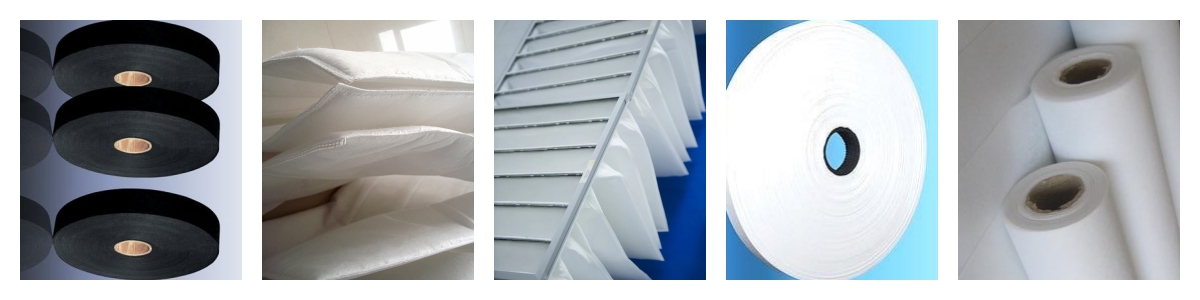

Suitable for welding Non-woven Cable water blocking tape. It can be used in thermoplastic, PVC laminated fabrics, Vinyl coated fabrics, Vinyl Films, Polyurethane (PU) coated fabrics

About Non-woven Direct Heat Welding Machine:

The multi-step sealing control process creates the most beautiful and sturdy seams and is easy to use and simple.

Mainly providing heat-compression products Pressing force driven by the pressure cylinder moves down and up the electrode so that the heat sealing product greatly increased the degree of pressure where product quality can be guaranteed; Pressure is set by the PLC according to system parameters which can be manually adjusted.

The machine pressure transmission system is composed of gas source, solenoid valve, cylinder, pressure head, foot switch, etc. The PLC is used to control the electromagnetic valve switch to move the cylinder and drive the pressure head to complete the material compaction, release or platform forward and return.

The local control play an important role which is divided into manual, automatic heat control two modes. The control box panel is provided with a lock transfer switch for conversion.

The working principle of the machine is pulse welding, which is mainly suitable for the production factory of cable water blocking tape.