High Frequency PVC Membrane Structure Welding Machine

- Information

- Product Description

- Video

- Download

High Frequency PVC Membrane Structure Welding Machine

Machine Features:

Lighting of the station projector lamp.

Infrared ray positioning device.

High sensitive spark protection, one-millionth of a second off protection.

Equipped with positioning wheel, mobile positioning is easy to solve.

Line filter protection avoid electric field radiation and make the equipment stable operation.

Specifications:

Type | Power KW | Frequency MHz | Tube model | Pressure Kg | Working electrode size | Remark |

YF-HFM8-A | 8 | 27.12 | 7T69R | 500 | Customized according to car carpet | pneumatic |

YF-HFM8-B | 5000 | hydraulic | ||||

YF-HFM8-C | >1000 | |||||

YF-HFM15-A | 15 | 8T85 | 2000 | |||

YF-HFM15-B | >2000 | |||||

YF-HFM15-C | >2000 | |||||

| YF-HFM25-A | 25 | 8T25R | 2000 | |||

| YF-HFM25-B | >2000 | |||||

| YF-HFM25-C | >2000 |

High Frequency PVC Membrane Structure Welding Machine application range:

HF welder can be widely used in production of small and large format tensile structures, membranes, tarpaulin, tents, oil booms, truck covers, swimming pool liners & covers, airline hangars, large billboards, fast doors, side curtains, etc.

About High Frequency PVC Membrane Structure Welding Machine:

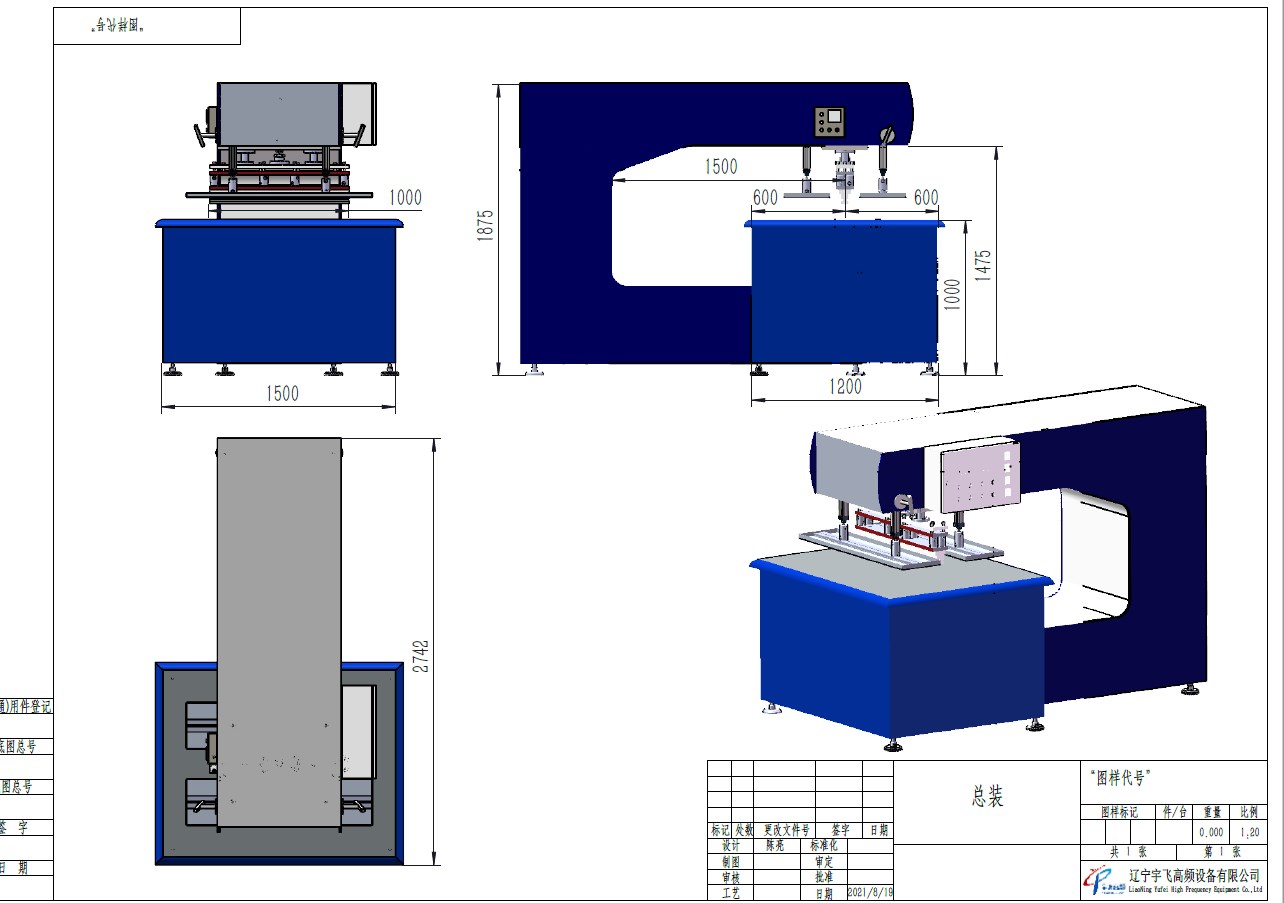

This type of high-frequency equipment is customized for customers, and the high-frequency cabinet is under the lower board. This design can increase the size of the desktop, increase the distance between the mold and the cantilever, and obtain a larger operating space without affecting welding.

The power of this membrane welding equipment is 25kw, and the maximum size of the customized mold is 3*110cm, and the welding effect is good. The whole machine is packed and transported in a wooden case. It can be used after simple core accessories installation.

This equipment is equipped with laser positioning, more accurate welding. The front and rear grounding plates of the equipment can be independently controlled. The operation of the equipment is simple, and the customer feedback that the welding effect is very good.

Details:Automatic clamping of mould (pneumatic clamping, saving mode and adjusting time)

Welded products:

Equipment appearance design

![]()

High efficiency HF weld cycles 8/12/15/25kW output power

Universal applied in PVC, PU, TPU, reinforced technical textiles

C-frame rolled steel structure with excellent strength and work ergonomics

The equipment is integrated with the main frame to minimize the floor space.