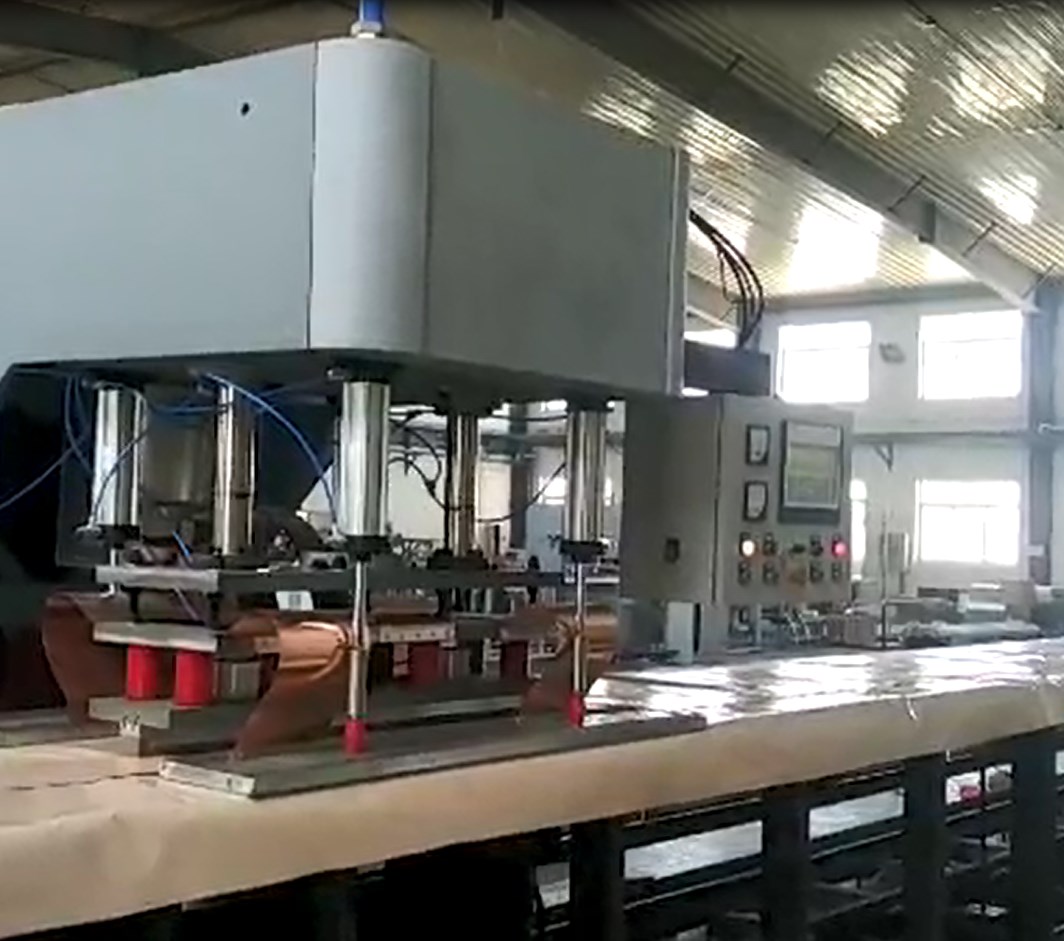

Radio Frequency Pvc Tarpaulin Welding Machine

- Information

- Product Description

- Video

- Download

Radio Frequency Pvc Tarpaulin Welding Machine

Machine Features:

PLC control, touch screen operation.

Prestore of a large amount of technical parameters.

Set technology parameters digitally in different times.

Fault self-diagnosis and screen displaying.

The table is designed with negative pressure adsorption to prevent material slippage.

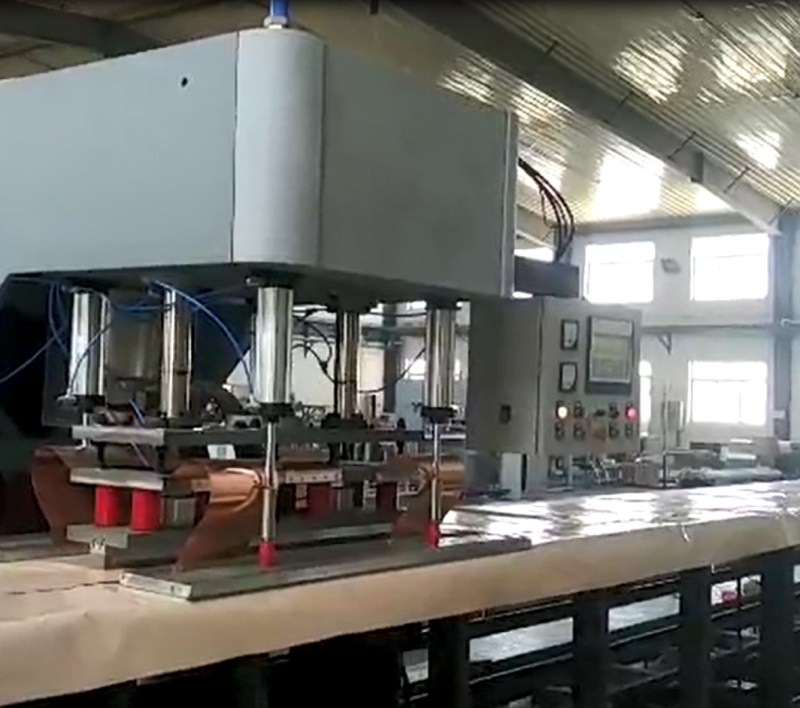

There are two walking tables on the back of the press. The operator can operate the machine with the press.

Specifications:

Type | Power KW | Frequency MHz | Tube model | Pressure Kg | Working electrode size | Remark |

YF-HFM8-A | 8 | 27.12 | 7T69R | 500 | Customized | pneumatic |

YF-HFM8-B | 5000 | hydraulic touch screen display Automatic Power Tracking Automatic track infrared positioning | ||||

YF-HFM8-C | >1000 | |||||

YF-HFM15-A | 15 | 8T85 | 2000 | |||

YF-HFM15-B | >2000 | |||||

YF-HFM15-C | >2000 | |||||

| YF-HFM25-A | 25 | 8T25R | 2000 | |||

| YF-HFM25-B | >2000 | |||||

| YF-HFM25-C | >2000 |

Radio Frequency Pvc Tarpaulin Welding Machine application range:

Automated travelling head high frequency welding machine, specializing in the production of architectural stretch film structure, tents, truck tarpaulins, PVC oil tanks, large advertising cloths, fast doors, swimming pool liners & covers, large inflatable models, airline hangars and so on. Special pulse welding can be used as auxiliary welding such as for non-HF weldable fabrics such as PE and PP.

About Radio Frequency Pvc Tarpaulin Welding Machine:

PLC and color touch screen control

Multiple sets of process parameters can be pre-stored for different materials and products and can be called at any time.

Highly sensitive spark protection circuit

Intelligent high frequency power adjustment is achieved.

Automatic lifting of molds by pneumatic system

Humanized design with station lighting

The table is designed with negative pressure adsorption to prevent material slippage.

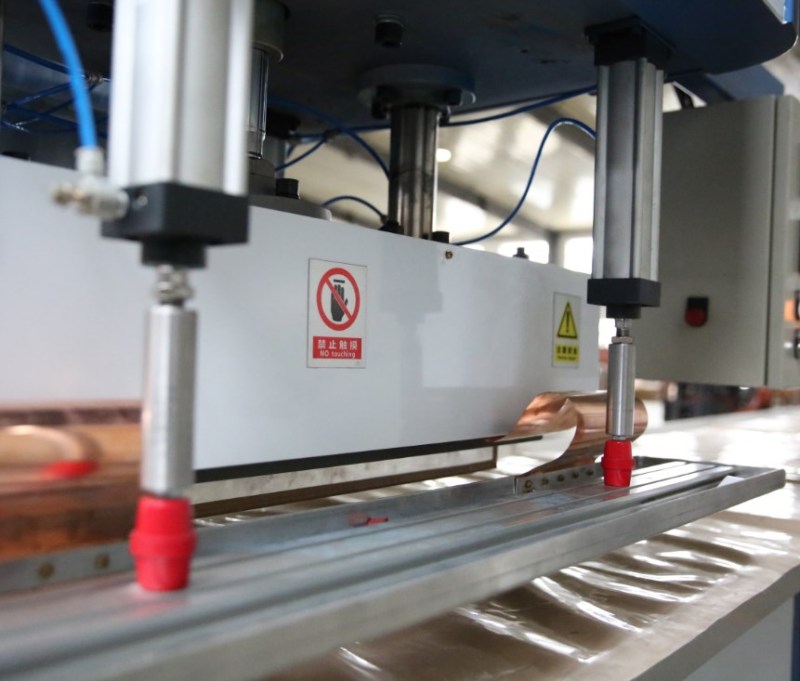

The press moves along the precision linear slide to ensure high-precision operation.

The machine can be controlled in multiple positions with a control box on both sides and a workstation.

Details:

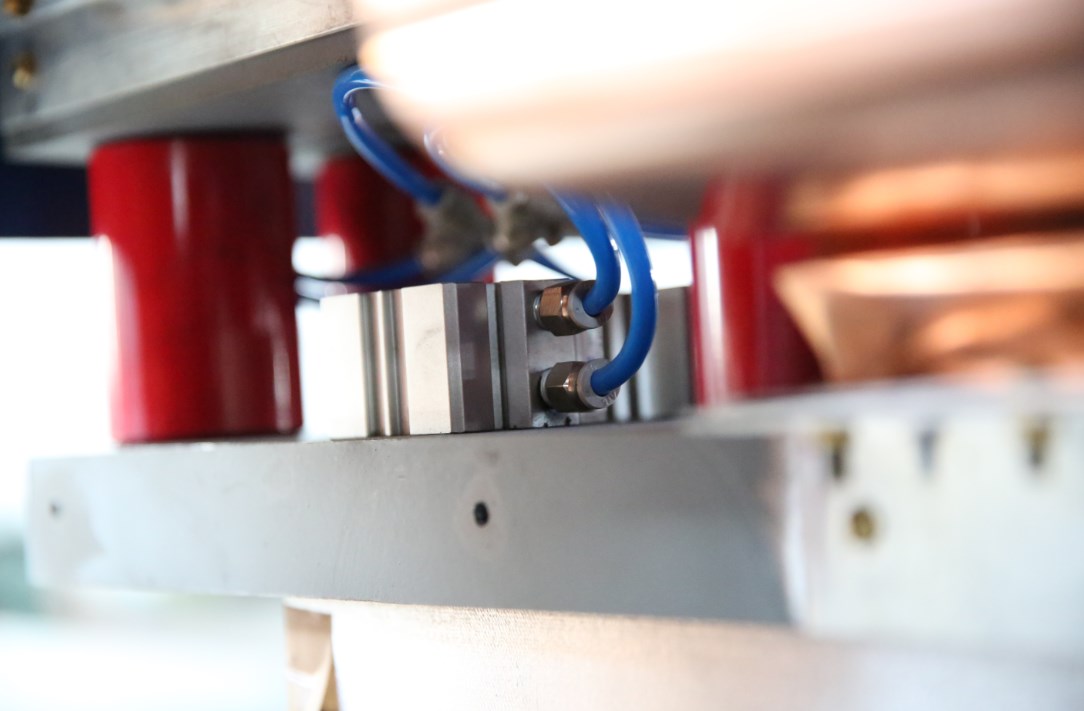

Pneumatic clamping of the mold, easy and quick replacement

Welded products

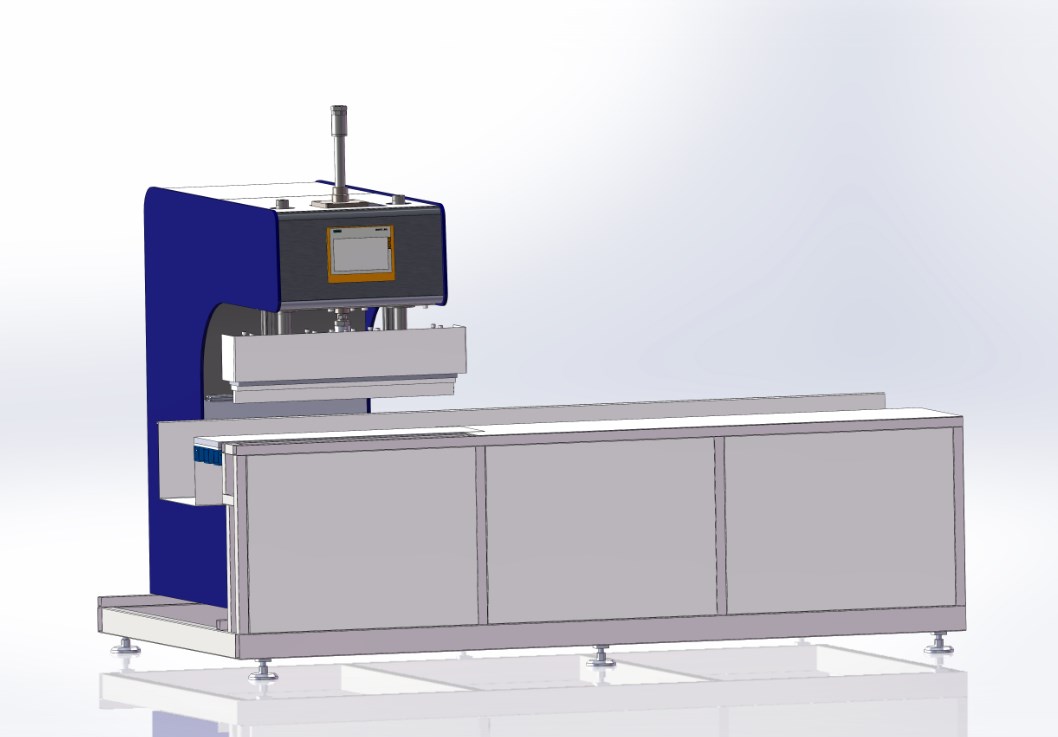

Equipment appearance design