High Frequency PU PVC Car Seat Embossing Machine

- Information

- Product Description

- Video

- Download

High Frequency PU PVC Car Seat Embossing Machine

Machine Features:

Over current protection, effective protection of electronic tubes.

High sensitive spark protection system, improve product qualification rate, protect mold and work-piece from fire damage.

Copper core transformer, stable and durable.

Line filters protection; avoid electric field radiation, equipment stable operation.

High frequency cabinet is integrated with main frame to save floor space.

High sensitive spark protection.

Slide platform to improve work efficiency.

Installation of positioning type universal casters, mobile positioning easy to solve

Specifications:

Type | Power KW | Frequency MHz | Tube model | Pressure Kg | Working electrode size | Remark |

YF-HFM8-A | 8 | 27.12 | 7T69R | 500 | Customized | High sensitive spark protection. Copper core transformer, stable and durable. Automatic double slide |

YF-HFM8-B | 1000 | |||||

YF-HFM15-A | 15 | 8T85 | 500 | |||

YF-HFM15-B | >1000 | |||||

| YF-HFM25-A | 25 | 8T25R | 1000 | |||

| YF-HFM25-B | >1000 | |||||

| YF-HFM35-A | 35 | 8T87R | 1000 | |||

| YF-HFM35-B | >1000 |

High Frequency PU PVC Car Seat Embossing Machine application range:

The machine with automatic, pneumatically driven work trays are perfect for serial production of blister & clam shell packages, medical containers such as blood or ostomy bags, laboratory, rehabilitation equipment, car floor mat, automotive parts and assemblies, cosmetics, etc. Heated electrode plate with temperature presets gives high accuracy for consistent welding of hard PVC/PET foils or PU foams.

About High Frequency PU PVC Car Seat Embossing Machine:

high frequency machine important spare parts are made from genuine electronic components from Japan, Germany, the United States, and Taiwan.

Strong output power: low-loss coaxial oscillator, coherent tuner, output force to shorten the welding time, increase production.

Frequency stability: The use of international industrial band 27.12MHz, the output cycle rate is stable, in line with international industrial band standards.

Anti-jamming device: equipped with frequency stabilizer and high-frequency magnetic field shielding system device to minimize high-frequency interference.

Safety performance: Regardless of sudden power failure or stoppage, the machine is stationary and will not suddenly rise or fall, raising workers' operational safety issues.

Heating function: suitable for different product processing needs.

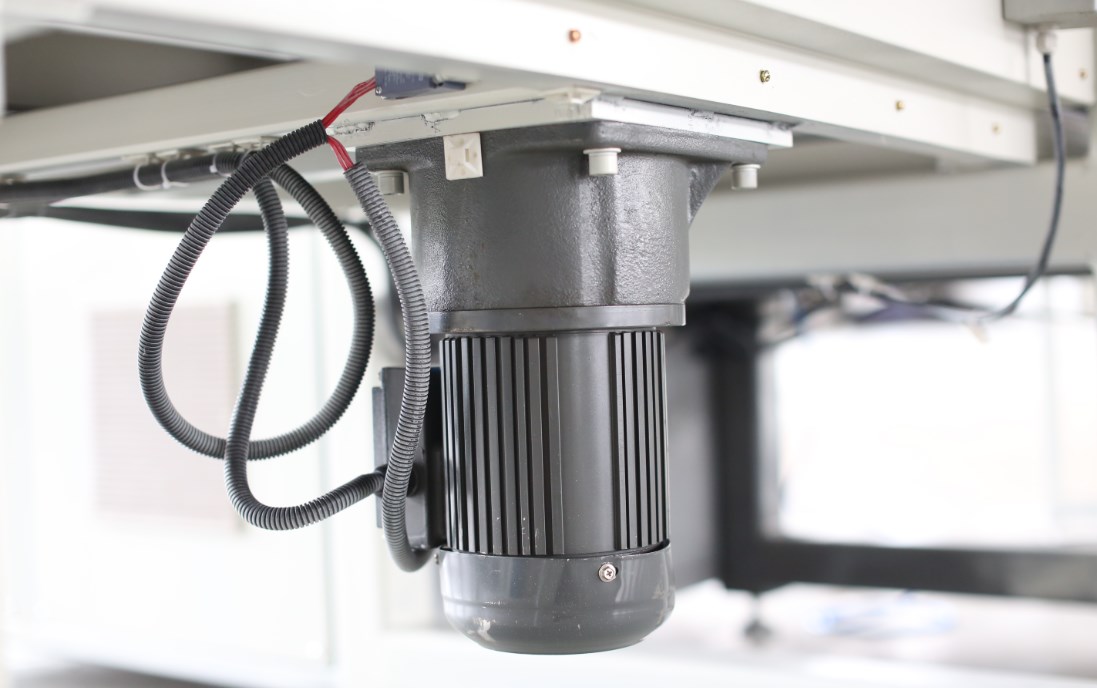

Details:The entry and exit of the sliding table is driven by the motor, which improves efficiency and safety

Welded products:

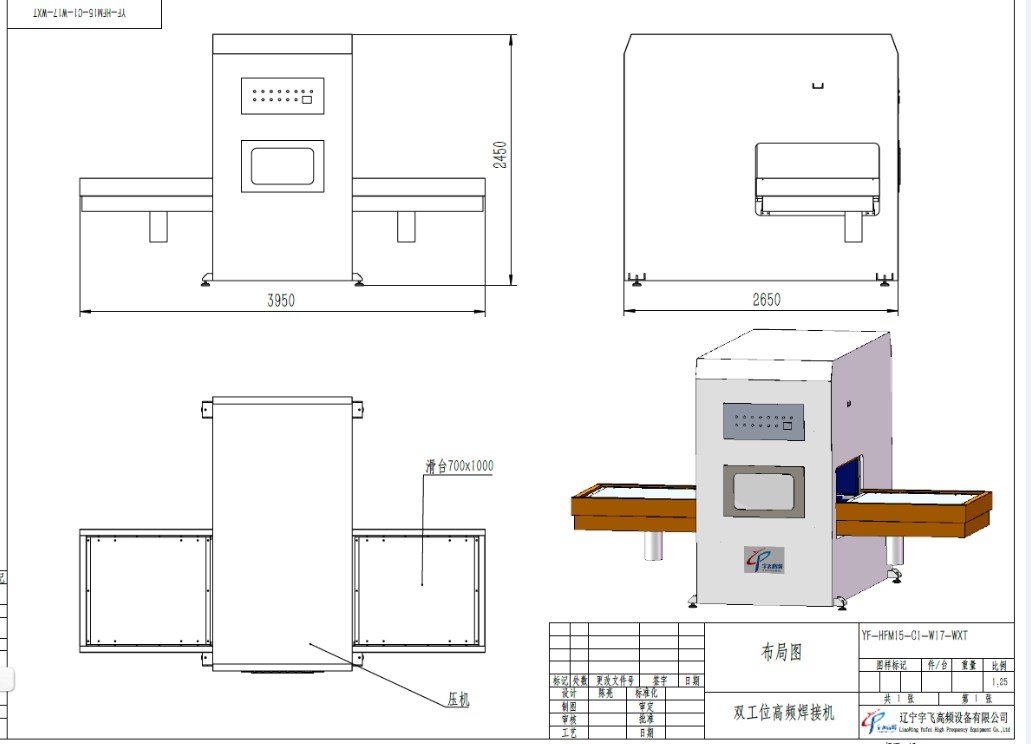

High frequency equipment design drawing

This machine is equipped with a quick-change 4-point electrode fixture, which can be pneumatically clamped to fix the mold. Custom tools and electrodes are available upon request.

Four-column presses can provide greater pressure