PLC Controls High Frequency Leather Embossing Equipment

- Information

- Product Description

- Video

- Download

PLC Controls High Frequency Leather Embossing Equipment

Machine Features:

Over current protection, effective protection of electronic tubes.

High sensitive spark protection system, improve product qualification rate, protect mold and work-piece from fire damage.

Copper core transformer, stable and durable.

Line filters protection; avoid electric field radiation, equipment stable operation.

High frequency cabinet is integrated with main frame to save floor space.

High sensitive spark protection.

PLC touch screen control

Automatic tracking and adjustment of welding parameters, fault self-test feedback.

Pneumatically clamp the mold, which can automatically identify the mold and call the welding parameter formula.

Specifications:

Type | Power KW | Frequency MHz | Tube model | Pressure Kg | Working electrode size | Remark |

YF-HFM15-A | 15 | 8T85 | 500 | According to product demand | hydraulic PLC touch screen control Automatic Power Tracking | |

YF-HFM15-B | >2000 | |||||

| YF-HFM25-A | 25 | 8T25R | 1000 | |||

| YF-HFM25-B | >2000 | |||||

| YF-HFM35-A | 35 | 8T87R | 1000 | |||

| YF-HFM35-B | >2000 |

PLC Controls High Frequency Leather Embossing Equipment application range:

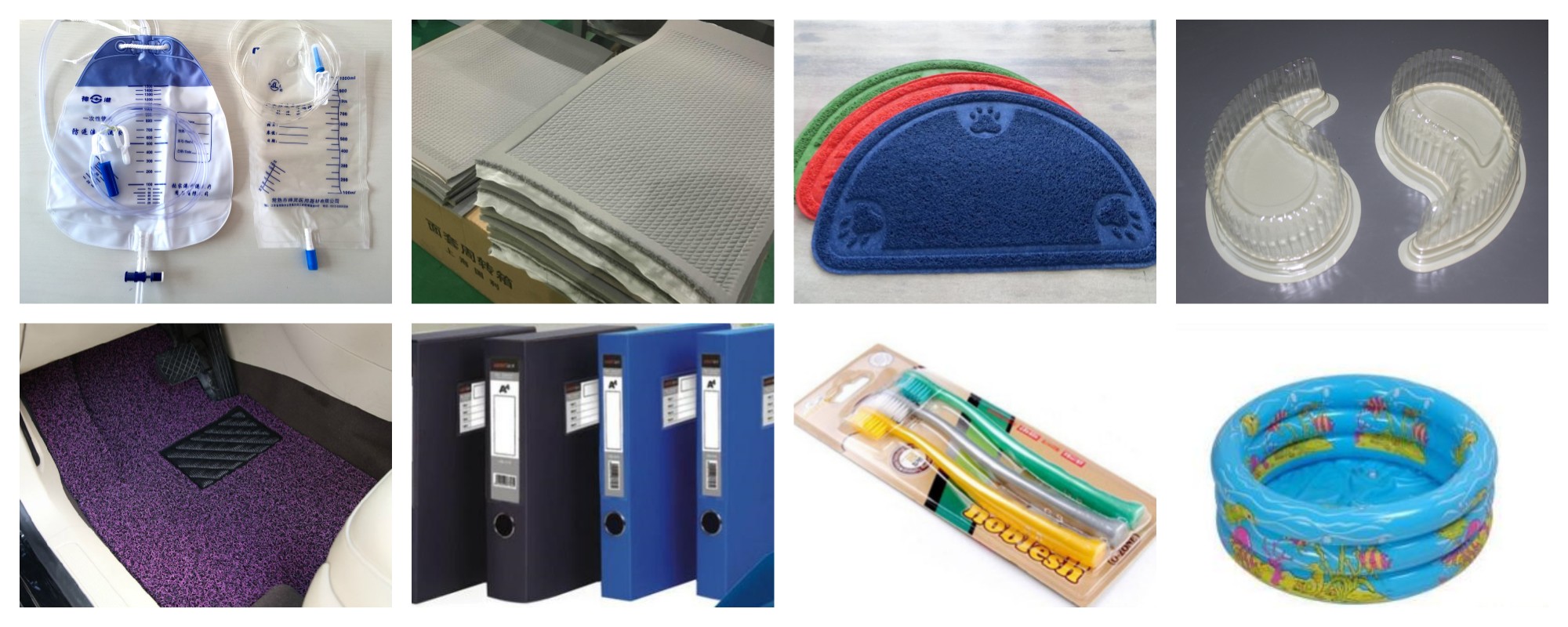

This high frequency machine is ideal for mass production of blister and clamshell packaging, medical containers such as blood or bone bags, laboratories, rehabilitation equipment, automotive floor mats, embossing of automotive seats, automotive parts and assemblies, and more.

About PLC Controls High Frequency Leather Embossing Equipment:

HF output power ranges of 8, 15, 25 and 35kW

Side Load Pneumatic Shuttle Work Tray (1 or 2)

Heated electrode clamps up to 160°C

Sealing efficiency from 1kW: 25cm2 standard PVC material

Precision Welding and Sealing with the WCS™ Welding Control System

Easy conversion to standard heat sealer

10" color touch screen programmable HMI with PLC

Memory storage and easy sorting 1000 recipes per work tray

Built-in VPN client and VNC server, WAN-LAN and USB I/O

Universal for PVC, PU, PET, A-PET, PLA film

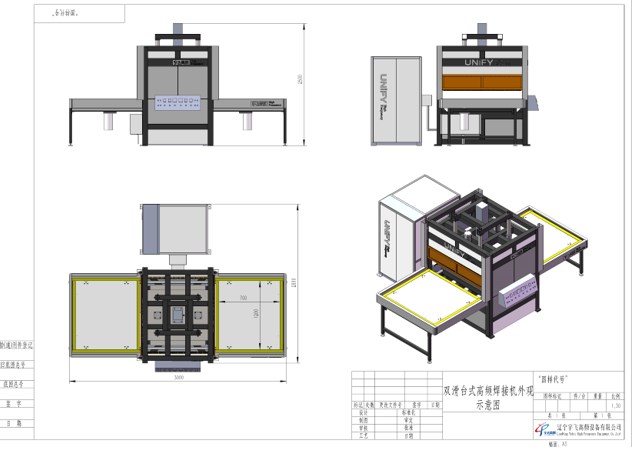

H-shaped steel frame steel structure and double-wing front access door

ATS™ auto-tuning and ultra-fast ARC limiter (solid-state image stabilization)

Automatic smooth slide work plate

Easy to install electrode replacement system on the upper platen

Fully screened HF welding area with pneumatic safety doors

Details:Independent operation cabinet, equipped with PLC touch screen control system

Welded products:

High frequency equipment design drawing:

Can provide greater power and pressure (optional hydraulic or pneumatic) to achieve welding of various types of products.