High Frequency Ring And Angle Cap Drying Machine

- Information

- Product Description

- Video

- Download

High Frequency Ring And Angle Cap Drying Machine

Machine General Features:

1, peripheral high frequency electromagnetic shielding device.

2, four-post type compressor, high strength, good rigidity.

3, the Japanese original 8T25 and domestic 834 Toshiba electron tubes for choice.

4, high sensitive spark discharge protection device.

5, hydraulic air cooling, can be used in high temperature environment.

6, the equipment can work continuously for a long time.

Specifications:

Model | Power Kw | Frequency | Tube model | Pressure | Working electrode size mm | Remark |

YF-HFM15-B | 15-50Kw | 27.12MHz | 8T85 | >20T | 600×1000 | hydraulic touch screen display Automatic Power Tracking |

YF-HFM15-D | 8T85 | >20T | 600×1000 | |||

YF-HFM25-B | 8T25R | >20T | 600×1000 | |||

YF-HFM25-D | 8T25R | >20T | 600×1000 | |||

YF-HFM35-B | 8T87R | >30T | 700×1200 | |||

YF-HFM35-D | 8T87R | >30T | 700×1200 |

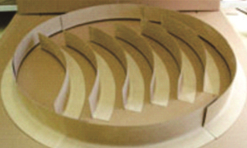

High Frequency Ring And Angle Cap Drying Machine application range:

High frequency drying equipment is mainly used for drying and forming products such as insulating cardboard.At the same time the machine can be used for wood drying.

About High Frequency Ring And Angle Cap Drying Machine:

This high-frequency drying equipment does not need any auxiliary equipment, and the drying and setting process of the insulating molded parts can be completed with one button after power-on and feeding, and the operation is very simple. The equipment has no dust, smoke, high temperature and other environmental pollution. National high-frequency electric field leakage standard: 25V/m. Our company's equipment adopts multiple means to shield tightly. The measured leakage value is only 0.2-1V/m, which is more than 20 times better than the national standard. Effectively protect the human body and other equipment from high-frequency electric fields.

1. Fast heating, high efficiency and energy saving.

2. Thorough drying, uniform temperature inside and outside.

3. Improve product quality and adapt to higher-grade insulation requirements.

4. Simple operation, safety and environmental protection.