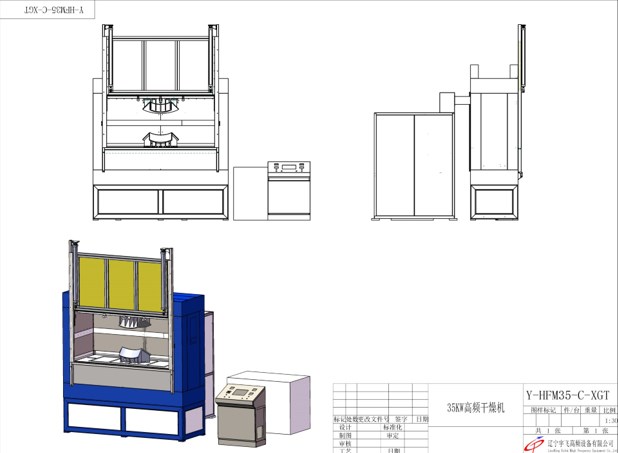

Rf Dryer For Transformer Insulation Carboard

- Information

- Product Description

- Video

- Download

Rf Dryer For Transformer Insulation Carboard

Machine General Features:

1, peripheral high frequency electromagnetic shielding device.

2, four-post type compressor, high strength, good rigidity.

3, the Japanese original 8T25 and domestic 834 Toshiba electron tubes for choice.

4, high sensitive spark discharge protection device.

5, hydraulic air cooling, can be used in high temperature environment.

6, the equipment can work continuously for a long time.

Specifications:

Model | Power Kw | Frequency | Tube model | Pressure | Working electrode size mm | Remark |

YF-HFM15-B | 15-50Kw | 27.12MHz | 8T85 | >20T | 600×1000 | hydraulic touch screen display Automatic Power Tracking |

YF-HFM15-D | 8T85 | >20T | 600×1000 | |||

YF-HFM25-B | 8T25R | >20T | 600×1000 | |||

YF-HFM25-D | 8T25R | >20T | 600×1000 | |||

YF-HFM35-B | 8T87R | >30T | 700×1200 | |||

YF-HFM35-D | 8T87R | >30T | 700×1200 |

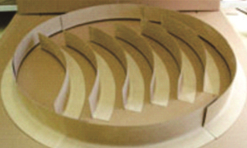

Machine application range:

High frequency drying equipment is mainly used for drying and forming products such as insulating cardboard.At the same time the machine can be used for wood drying.

About hf dryer:

Different from traditional heating, high-frequency heating uses the super penetrating ability of high-frequency electric field (the penetrating ability of high-frequency electric field is much stronger than that of microwave) to repeatedly polarize the heated material molecules, resulting in severe friction, from the inside out. External self-heating. It does not need any preheating and heat conduction, so its heating efficiency is very high.

In addition, high-frequency heating is superior to traditional drying and microwave drying, that is, the electric field can realize selective heating through the mold, and concentrate energy on the parts that need heat, further avoiding unnecessary consumption. Therefore, not only can the energy be greatly saved, but also the heating time can be greatly shortened and the production efficiency can be improved.

Usually, the heating time of the corner ring with a length of 550mm and a thickness of 2.5-3mm does not exceed 6 minutes, and the heating time of the corner ring with a length of 700mm is 8 minutes. During the heating process of 6 to 8 minutes, the total consumption averages 1.3 kWh. If multiple layers of materials are put together to dry together, the cost will be further reduced.

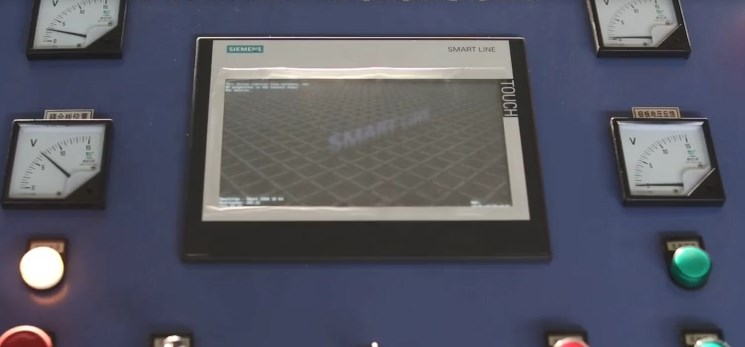

Hf dryer details:

When the equipment is working, the screen door is closed to effectively reduce electromagnetic radiation.

Starting the device requires two hands to ensure safety.

PLC touch screen control, multiple sets of parameters can be pre-stored, making the operation easier.

Hf dryer structure: